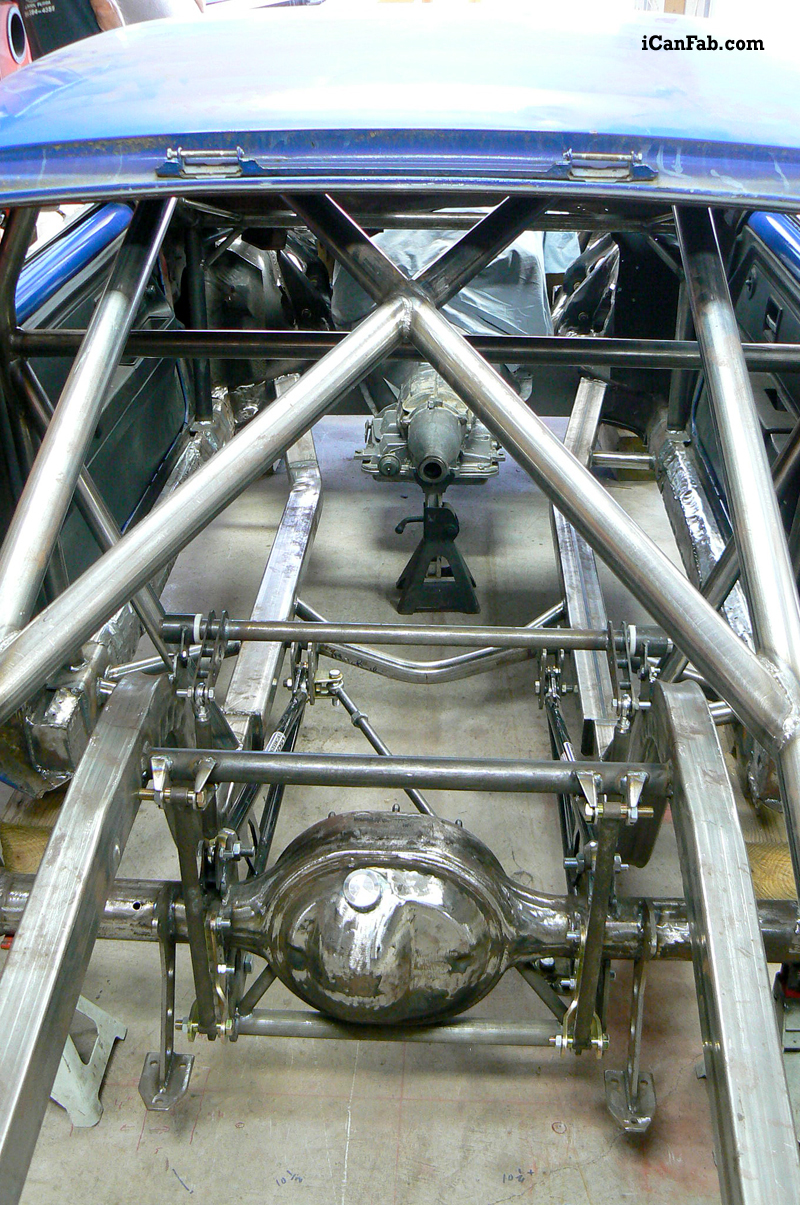

Roll cages work in a variety of car configurations, and play a large roll in a vehicles overall ET. All roll cages require different elements to the cage’s design depending on the type of car. This 1972 Vega had poor modifications done previously – so all was removed.

This new custom rollbar and roll cage is made with EWS 1 5/8 in. x 0.134 in. wall mild-steel tubing.

When finished this custom Vega chassis and roll cage – it will easily be NHRA certified to 8.50.